Notice: Trying to access array offset on value of type null in /srv/pobeda.altspu.ru/wp-content/plugins/wp-recall/functions/frontend.php on line 698

In instances where solely small quantities of pattern can be found, the furnace is the apparent selection. Sensitivity: The furnace has a distinct advantage over the flame close to the sensitivity and limits of detection. One motive is that your entire sample is put into the furnace whereas only 2% of the pattern makes it into the flame. Another is that the furnace integrates signal over the «puff» of atoms whereas the flame includes institution of a steady state studying. Right here, oxygen fuel is the most common oxidant. We can use a rotameter to monitor the movement rate of an oxidant and gasoline. Further, the rotameter is a vertically tapered tube, having the smallest finish positioned down, and a float is positioned contained in the tube. What is Electrothermal Atomization? Electrochemical atomization or electrothermal atomization is a method where a sample is passed by three phases in order to achieve atomization.

Evaluation of high-purity semiconducting supplies for the electronics business is without doubt one of the principal applications of the SIRIS methodology. The method can detect, for instance, indium in silicon at the one part per trillion degree. The high effectivity of the pulsed sputtering methodology makes it possible to document one depend attributable to indium on the detector for under 4 atoms of indium sputtered from the stable silicon goal. Analyses of interfaces are of rising importance as digital circuits develop into more compact, and in such designs matrix results are of great concern.

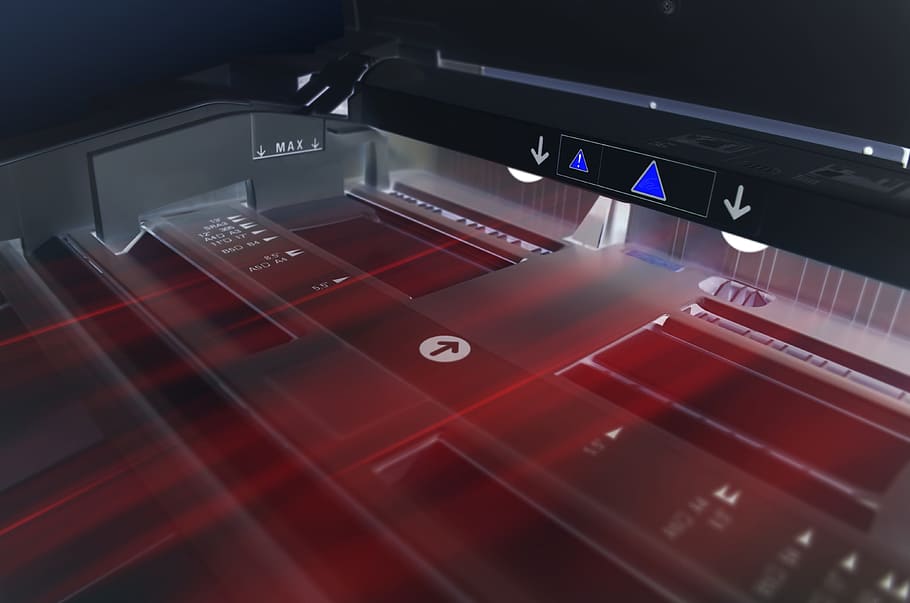

Liquid is shipped into the 2 spray orifices of nozzle tip and is atomized inside the orifices by shearing pressure. Then, the sheared liquid, when sprayed out from the orifices, is re-atomized by supersonic jet. Each fog stream, sprayed out from the 2 spray orifices apart, collides with one another in the middle and are further atomized by 33,000-forty,000 Hz ultrasonic waves. Because the outcome, generated is ultra-effective fog with uniform spray droplets distribution having no large particles. Basically, the sooner the gasoline hits the metallic, the better the powder. There are also different features of the powder which are improved by our process. The primary is the form of the powder. By blowing sizzling gas on the molten powder droplets, you give them a couple of more milliseconds to cool down and adopt the morphology with the lowest stage of floor tension. So, instead of settling in an elongated form, good spheres could be created. This is not attainable with gas atomizers because the cold gas freezes the elongated form of the atoms within the powder. The sphericity of a powder is essential for governing how a powder will behave in a 3D panda dtf printer.

Manufacturing of steel powder has been carried out for many years. Apart from some methods using crushers for powder production, the atomization of a molten liquid melt is the most common manner to produce steel powders. Therefore different melting technologies (open furnace, vacuum furnace, induction melting or plasma melting, and more) as well as atomization methods (water, gas) can be used. Relying on the melting and atomization technology used, the produced powder can differ in particular size and form. This article gives an summary of the most used applied sciences in melting and atomization with a particular give attention to the production of powder for the use in additive manufacturing. A extra detailed insight in the fuel atomization course of utilizing closed couple atomization system can also be a part of this text. There are a wide range of strategies that can be used to create atoms from molecular substances. The three major methods contain the use of a flame, a gadget often called a graphite furnace or a plasma. These three atomization methods are commonly used with liquid samples. Whereas there are numerous plasma devices which have been developed, solely the commonest one — the inductively coupled plasma — will be discussed herein.